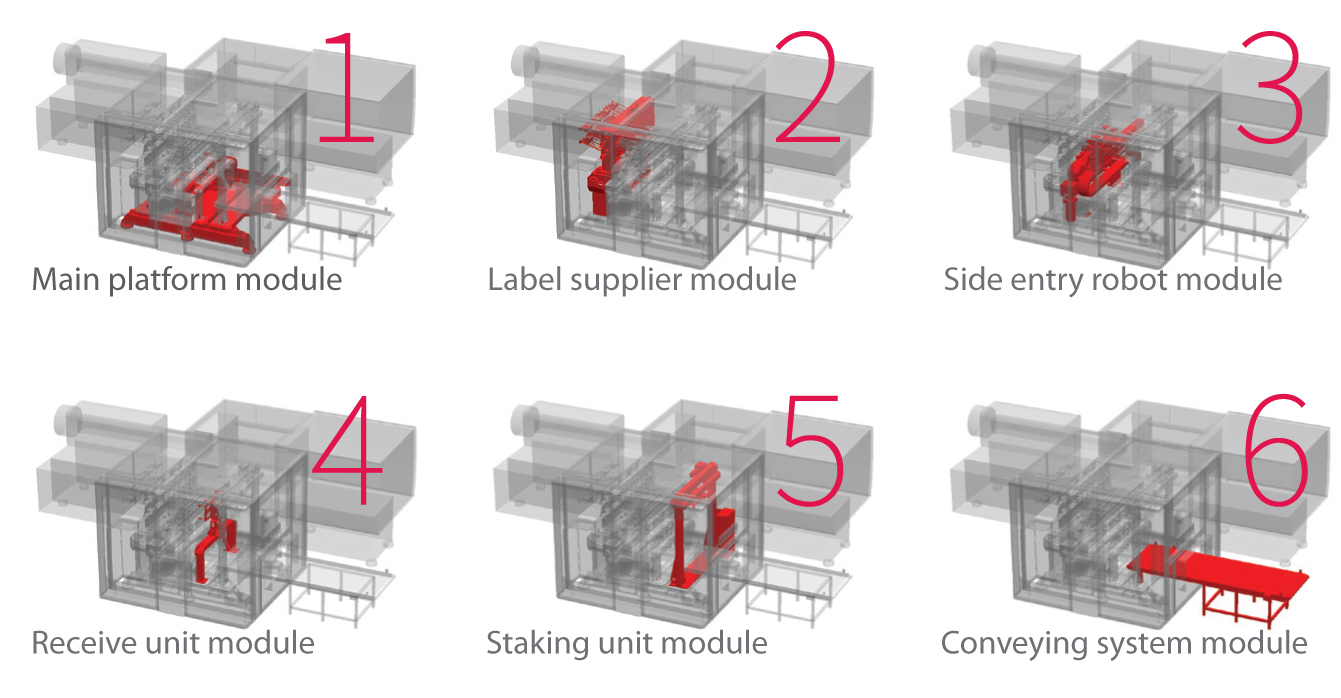

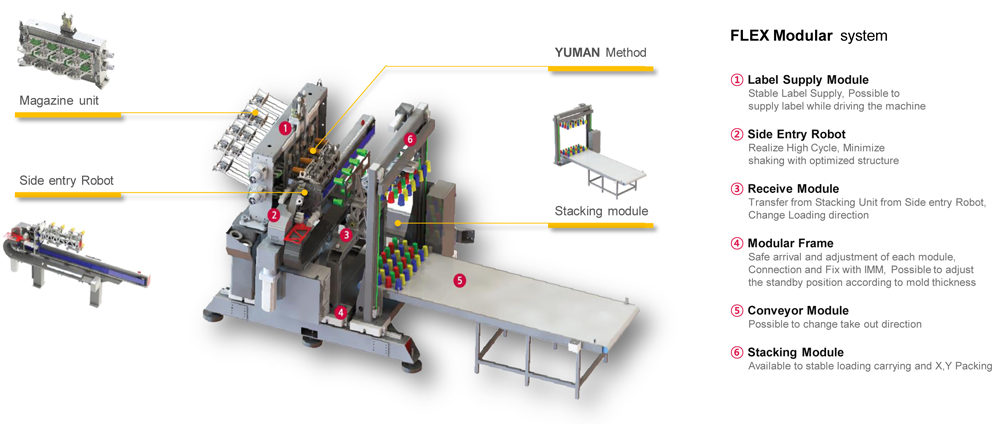

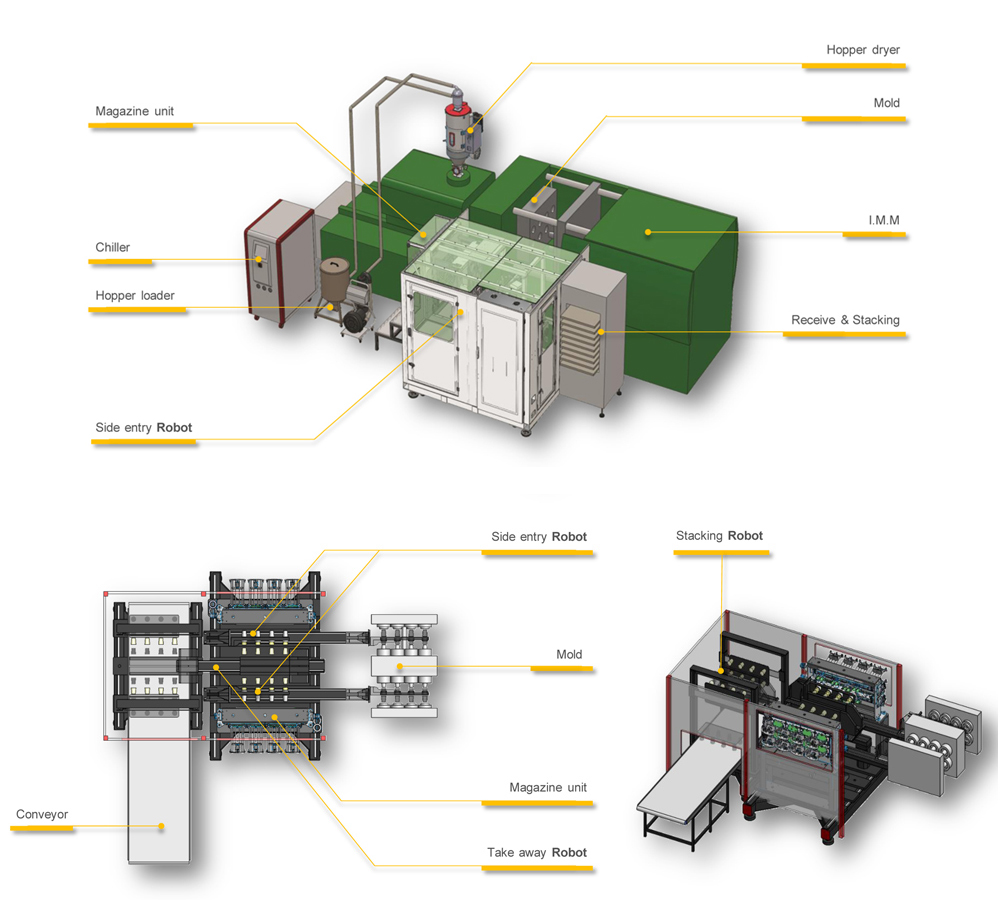

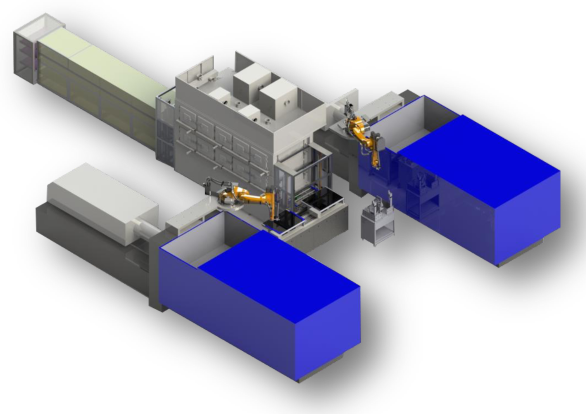

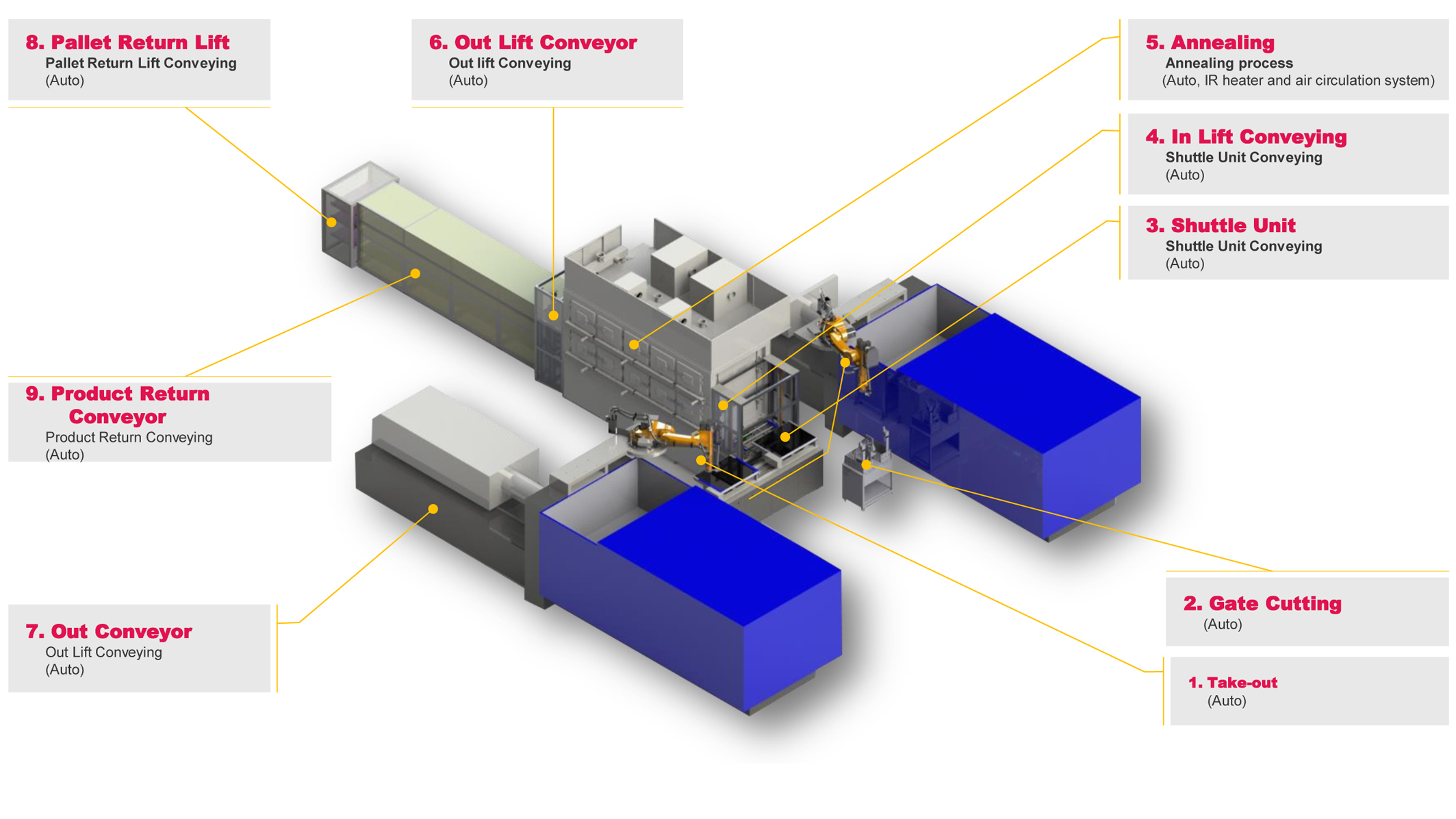

- FLEX Modular System

- Excellent expandability

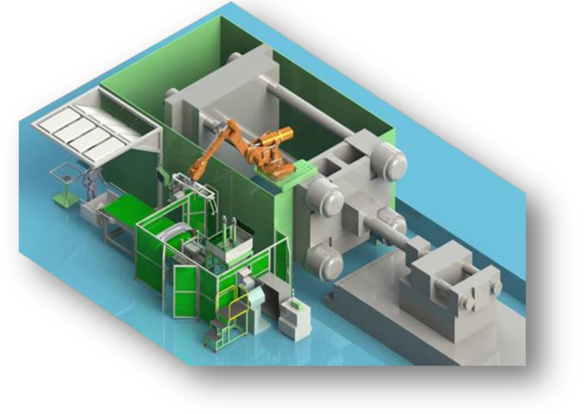

- Open and Shut magazine unit design

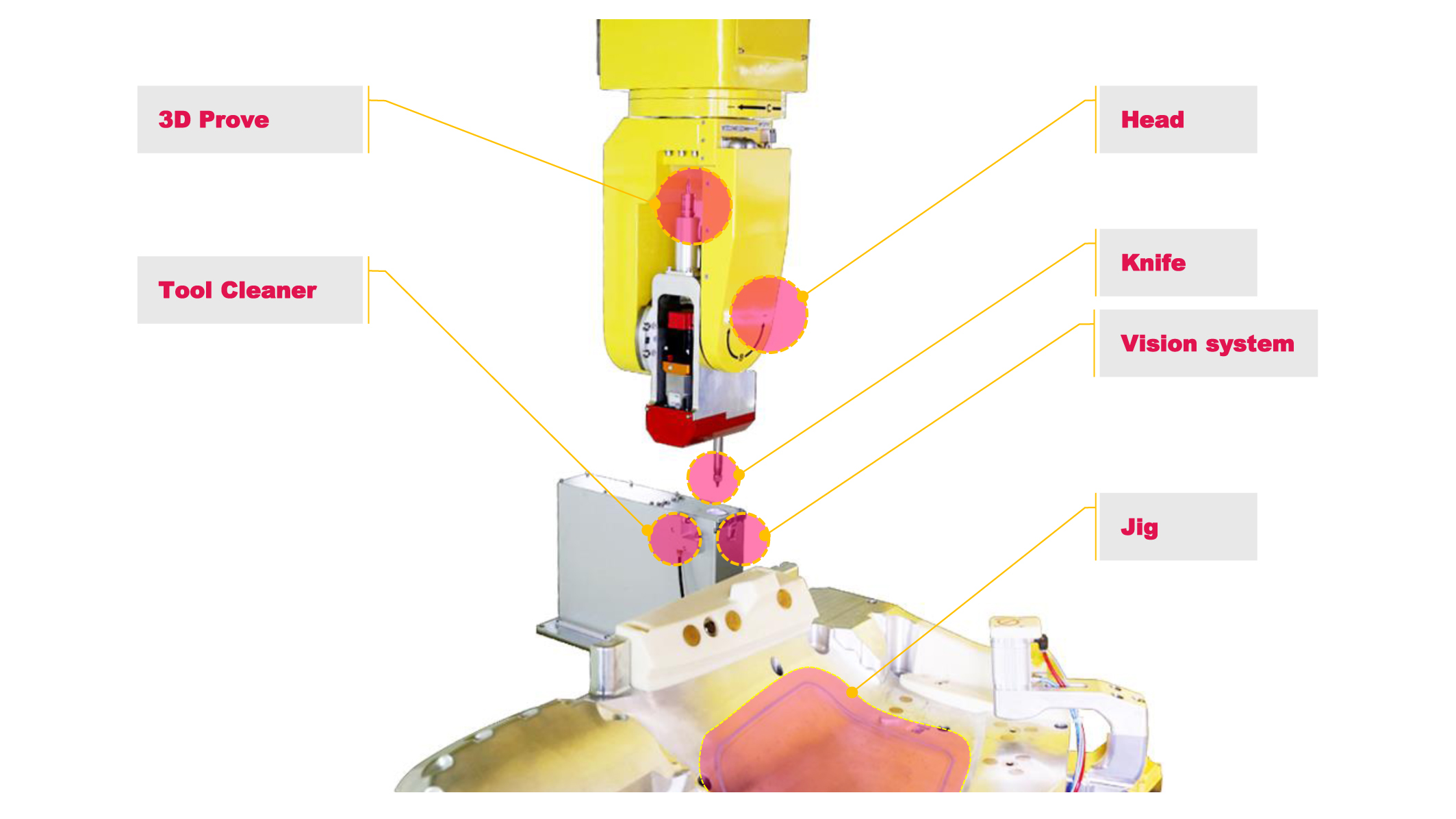

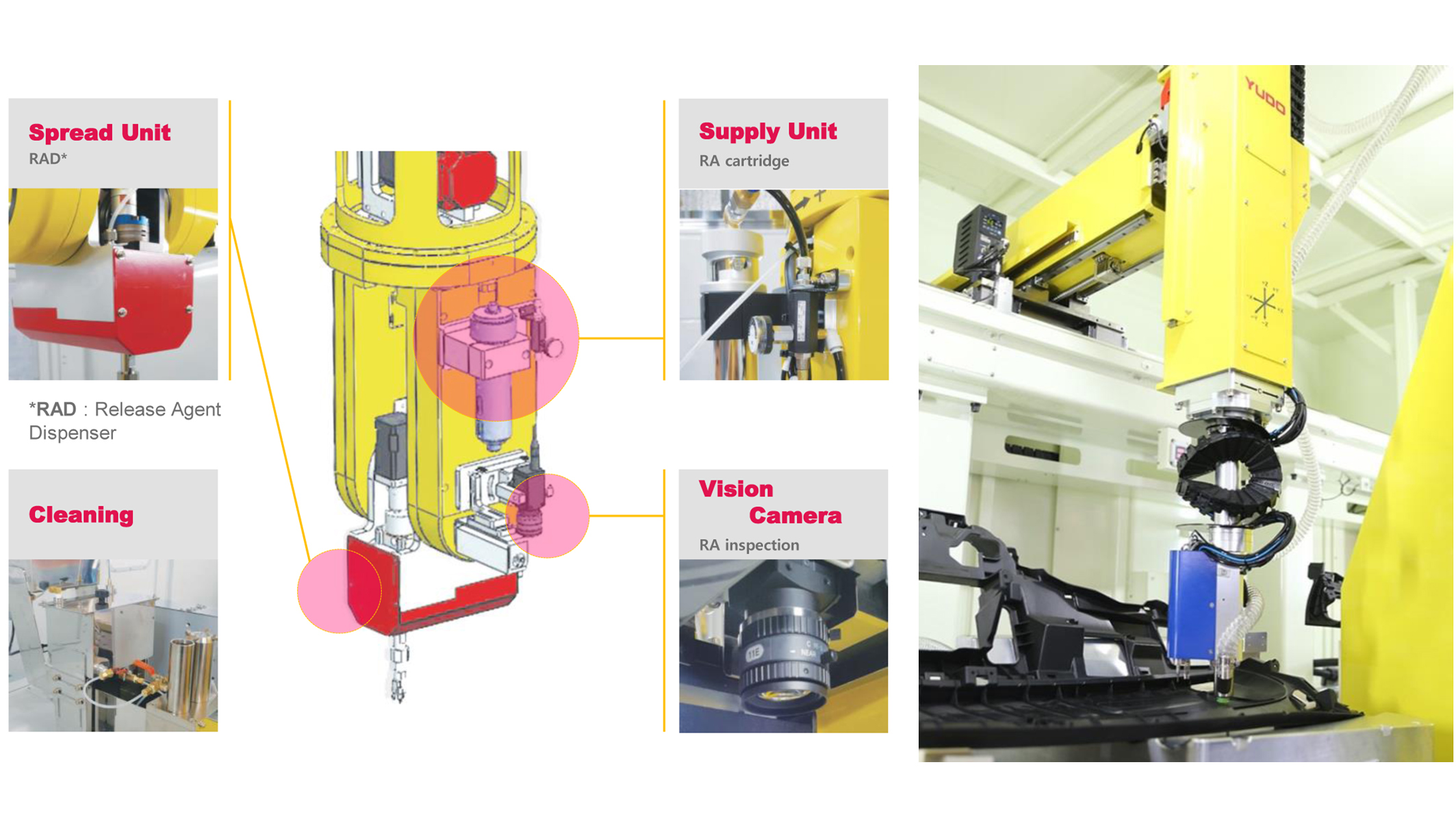

- Label Placement Calibration

- YUMAN method: Accurate label film absorption

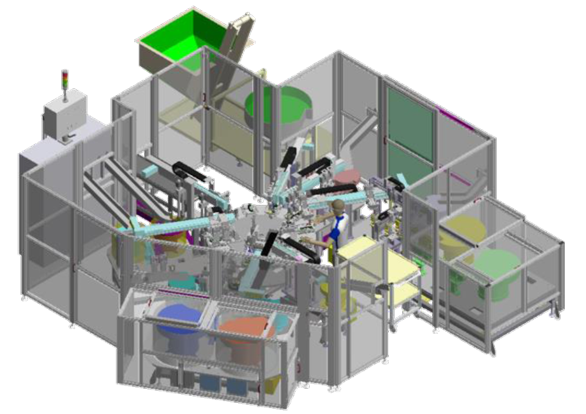

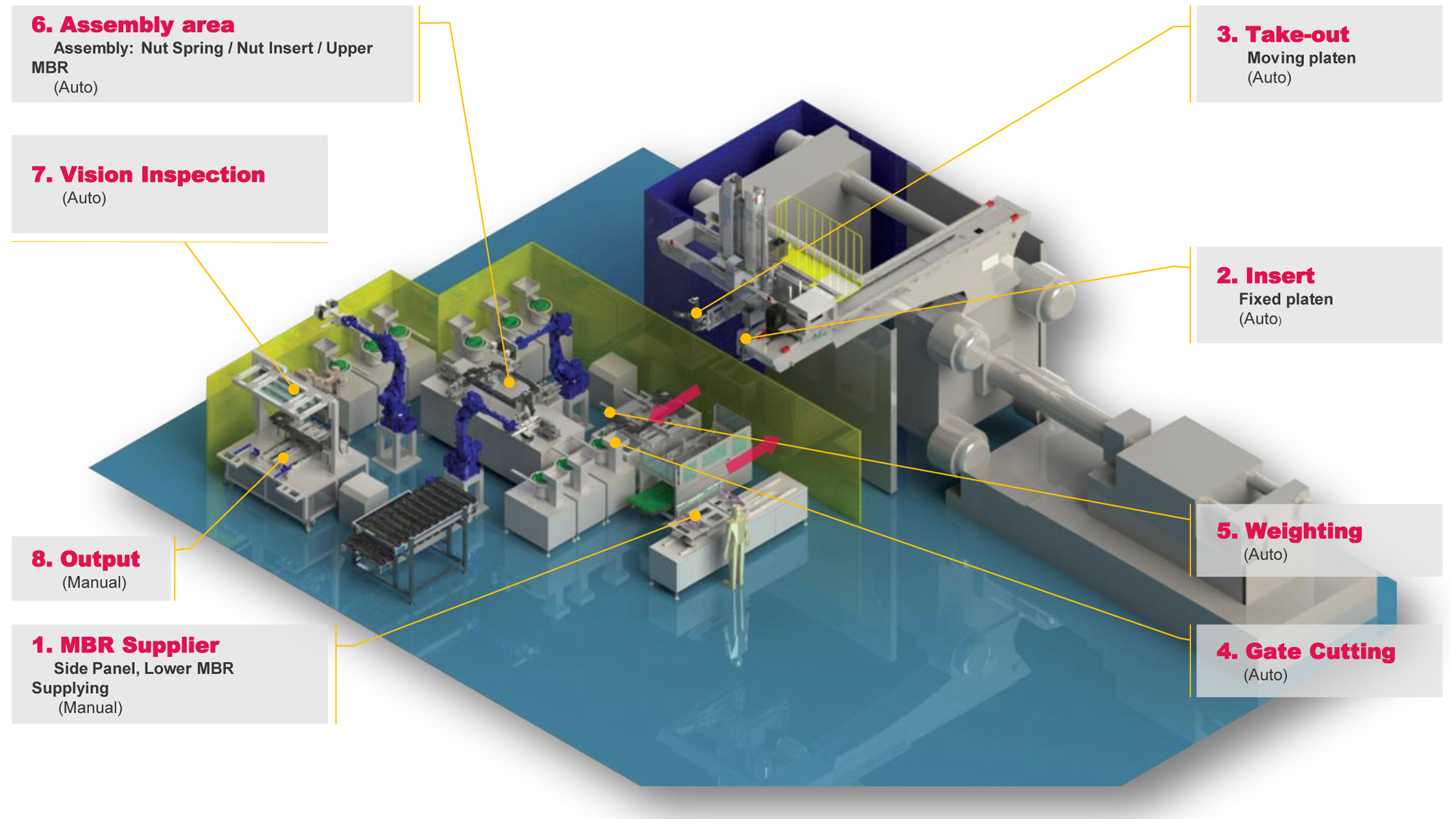

With its flexible modular system, FLEX IML machine able to be constructed around different mold types, equip additional modules for added assembly & inspection functionality. FLEX IML also greatly reduces costs and saves time when remodelling units to produce new products

| Cavity | 4 | 6 | 8 | |

| Cavity composition (Row x Column) | 2 x 2 | 2 x 3 | 4 x 2 | |

| Entry stroke (mm) | 1750 | 2260 | ||

| Crosswise stroke (mm) | 150 | |||

| Positioning, repeatability (mm) | ±0.1 | |||

| Dry cycle time (sec) | 4.5 | 5 | ||

| Pneumatic supply (bar) Mpa | (6)0.6 | |||

| Air Consumption (NI/min) | 850 | 1100 | ||

| Electrical supply | AC220V, 50/60Hz | |||

| Installed nominal power (kW) | 18 | |||

| Dimension (mm) | A | 2100 | ||

| B | 1800 | 2280 | ||

| C | 330 | 410 | ||

| D | 340 | 370 | ||

| E | 2470 | 3060 | ||

| F | 2300 | |||